Some of you might not even know the reason WHY we live in Dublin, Georgia/USA...

Guess it's about time to tell you about that!

Let's start back in The Netherlands, or as they mention here Holland...

Husband Pieter shown here with a mushroom drawing and the Dutch flag wrapped around.

Limburg International Magazine had a publication about him in August of 1983

Drs. Pieter Vedder,

Vice-President of Camsco

On Page 22, the article appeared.

By the way, Limburg is the Dutch Province where I am born and grew up!

Pieter is born in the above Province of Gelderland...

Drs Pieter Vedder

becomes a Vice-president at Camsco

Drs Pieter J.C. Vedder, 54 who has headed the Mushroom Growing Training Centre in Horst, North Limburg, since its foundation in 1963 (Pieter was the founder!), has been appointed Vice President for Training and Development of the Mushroom Division of Campbell Soup Corporation in Dublin, Georgia, USA with effect from August 1st, 1983. He will be in charge of the training centre, combined with a mushroom farm for instruction purposes, currently being built in Dublin for Camsco Mushroom Company Inc. by Veciap Holland, a consortium of three North Limburg companies (see Headlines in the Limburg International Magazine issue for April 1983).

"My role within the Campbell organization is a dual one," explains Pieter Vedder "On the one hand, I will be expected to be actively involved as a board member in present and future developments in the field of mushroom growing and, on the other, I am responsible for training company staff in this field."

Pieter Vedder ranks as one of the scientific pioneers of mushroom growing in the Netherlands which is now the fourth largest mushroom producer in the world after the United States, France and China.

Virtually all the Dutch growers received their initial and "in-service" training at the Training Centre in Horst (called the C.C.O. after its Dutch initials) which remained the only teaching unit of its kind in the world until the creation by Pieter Vedder in Dublin, Georgia of this second,

almost identical, school.

There are over 500 mushroom growers in the United States but about half the total production is supplied by only three percent of the companies. The largest producer is Castle & Cook, 30 million kg per year, followed by Buttler County, Campbell Soup and Ralston Purina which each produce about 20 million kg.

Campbell's Mushroom Division now operates nine mushroom farms. The tenth, with an annual production capacity of 3 million kg is currently being built in Dublin as a turnkey project by Veciap Holland and will begin production in October.

"Within the Campbell organization, there is a high level of technical skill in mushroom growing." comments Pieter Vedder who has maintained extensive links with Camsco for a number of years and has previously arranged courses given to staff within the company.

"Mushroom growing in the United States is generally characterized by constant levels of both production and quality. Yield per square meter and efficiency are both higher in the Netherlands but this is associated with general lower quality."

Pieter Vedder notes that the Campbell Soup Corporation - with its headquarters in Camden, New Jersey, over 100 production plants for foodstuffs and an annual turnover of three billion (Am.) dollars primarily supplies the market for fresh vegetables and processes into soup those not sold on any given day. "In the Netherlands, much to my regret, the reverse now applies. About 70 percent of total mushroom production is bottled or canned and primarily exported to West Germany where the Dutch product has to compete against those from Asia and Eastern Europe. If the Netherlands had concentrated on the export of fresh produce to West Germany, the only competition to be dealt with would be that of France."

Pieter Vedder, who has been associated with every development in Dutch mushroom growing since 1956, is leaving at a significant point in time. "Up to now, Dutch mushroom growers have regarded each other as colleagues but I expect that within a few years - as a result of tensions arising from price trends and the major expansion of a small number of real businesses - they will end up confronting each other as competitors just as has happened in the United States. That could mean that a lot of knowledge and research no longer benefits everybody and also results in the loss of the friendly relationship between the growers." ~ Jan Derix

A drawing of the Campbell Soup Corporations mushroom farm in Dublin, Georgia currently being built as a turnkey project by Veciap Holland. The view shows, in sequence from the back towards the front, the compost hall, the tunnel complex and the growing cells. The packing plant is on the right. The construction of the total 16,000 m² plant will cost 17 million guilders.

The prefabricated elements and all of the technical equipment were produced in the Netherlands. The plant will begin production (3 million kg per year) in October and will soon be expended by the addition of a school, headed by Drs. Pieter Vedder, that will feature an instruction farm and a research department.

Husband Pieter's design for labeling the mushrooms...

Husband Pieter's design for labeling the mushrooms...

Governor Joe Frank Harris speaks at Camsco dedication.

The industry employs 200 people and produces over 125,000 pounds of fresh mushrooms each week ― 85 percent of which are packaged fresh for the produce market and 15 percent of which are used in Campbell's Soup.

It was announced during Tuesday's ceremony that the local farm has been chosen as the site for a school to train personnel in the modern technology method of growing mushrooms.

Pieter Vedder, a Dutch citizen and world recognized expert on mushroom growing technology, heads the school.

The Laurens County facility was prefabricated in The Netherlands by Veciap and shipped and erected on site for a total $ 7.3 million investment. The current payroll for the operation is $ 2.5 million annually.

June 19, 1984 from the CEO of Campbell Soup: R. Gordon McGovern

DEDICATION OF THE DUBLIN MUSHROOM PLANT

Tuesday, June 12th, was really Pieter Vedder Day in Campbell Soup Company.

The Dublin, Georgia mushroom plant would not have been without your input.

We appreciate all the hard work and stress of putting such a project together and getting it started.

It was a fine day of dedication.

Thanks, again, for your major role.

Gordon McGovern

President

June 25, 1984 Dutch firm to build training center here

Camsco will use the new center to train personnel for employment in its existing and planned mushroom growing operations. The center will be modeled after the one located in Horst, The Netherlands, the only facility of its kind in the world.

The announcement said the Laurens County center will be managed by Pieter J.C. Vedder, vice president of Camsco Mushroom Co.

Vedder managed the Horst operation for many years. He was its founder as well!

"Veciap Holland's expertise has resulted in a very fine facility for Georgia," Harris said in the announcement. "This complex is the only such facility in North America and represents high technology at its best."

On July 30, 1984 We're Proud To Be A Part Of Laurens County

We Employ 225 Employees

April 23, 1985 We employ 220 people...

We Employ 225 Employees

April 23, 1985 We employ 220 people...

1986 ― Camsco spent $ 5.6 million in Dudley area during year and had an average employment of 223.

1987 ― Campbell's spent $ 6.2 million in Dudley during the last fiscal year. The farm, which employs around 195 people...

Meanwhile in Hillsboro, Texas another Dutch technology mushroom plant got erected with Pieter's help in design and training for the start up.

Here you see the aluminum shelf-beds being erected.

They also form a connection with the roof.

Official opening of the Hillsboro, Texas farm was on October 7, 1987

-- "In the last ten years, mushroom growing has changed from an art to a science," says Pieter Vedder, Campbell's expert in mushroom technology.

The Hillsboro, Texas farm was really a state of the art farm!

I, myself finally got to visit this farm when Pieter did a seminar for Campbell's and I was joining him on Monday, December 06, 1993.

1987 ― Campbell's spent $ 6.2 million in Dudley during the last fiscal year. The farm, which employs around 195 people...

Meanwhile in Hillsboro, Texas another Dutch technology mushroom plant got erected with Pieter's help in design and training for the start up.

Here you see the aluminum shelf-beds being erected.

They also form a connection with the roof.

-- "In the last ten years, mushroom growing has changed from an art to a science," says Pieter Vedder, Campbell's expert in mushroom technology.

I, myself finally got to visit this farm when Pieter did a seminar for Campbell's and I was joining him on Monday, December 06, 1993.

Don't forget to view video with subtitles/closed captions— way below post—bottom of related links...

When Pieter got 'forced' to move to Pennsylvania, we both decided to move to Italy and work there instead.This is what President Gordon McGovern wrote to husband Pieter:

Dear Pieter:

The announcement of your leaving for Italy could not pass by without my writing a note of thanks for your contribution to Campbell mushrooms.

You brought a world-renowned professionalism to our operations when they sorely needed expertise.

All of us here wish to express our appreciation and best wishes. We hope succeeding generations can live up to your standards.

Regards,

Gordon

A treasured 'mushroom' Editorial Review...

This is a slide that Pieter often used for his seminars...

Sadly, when CEO Gordon McGovern was no longer in charge, they started to do away with this successful motto of the past; QUALITY...

On January 22, 1992 Pieter received a nice photo album of Campbell Soup Company's Mushroom Operations.

This is an aerial view of the Dublin mushroom farm

This is nine years after its start and they had gone from producing mushrooms for the fresh market, by hand harvesting high quality, to only mechanical harvesting for the canned food plants.

Husband Pieter also was involved in the design of the Dutch technology Hillsboro, Texas farm, opened on October 7, 1987.

The Hillsboro farm originally was also designed and set up for producing hand harvested quality mushrooms for the fresh market...

It was very sad that they went from first quality, closed and firm button mushrooms to open, lower quality soup and canned product. That way also they opened the door for cheap mushrooms from e.g. China. Sure, it saves on the payroll as harvesting is the biggest part of labor but mechanical harvest never can yield high quality...

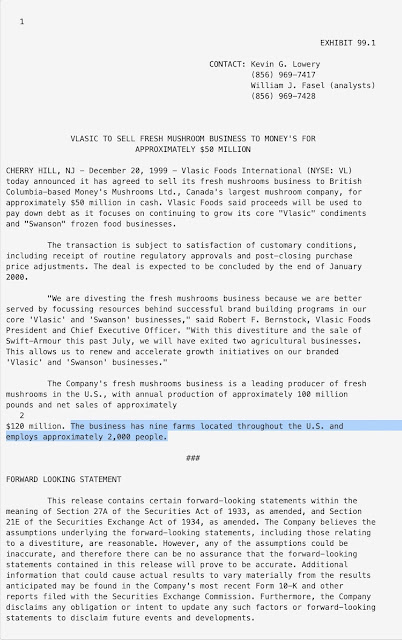

Campbell Soup decided to sell off all produce plants; a sad day for many that lost their jobs.

Money's a Canadian company loved to purchase the Dublin and the Hillsboro plants but they were kind of forced by Campbell Soup to purchase ALL of their nine mushroom plants!

That did not work out in the end... A SAD day.

Both of us had pledged to be involved in starting up again for the new owner and to train the people.

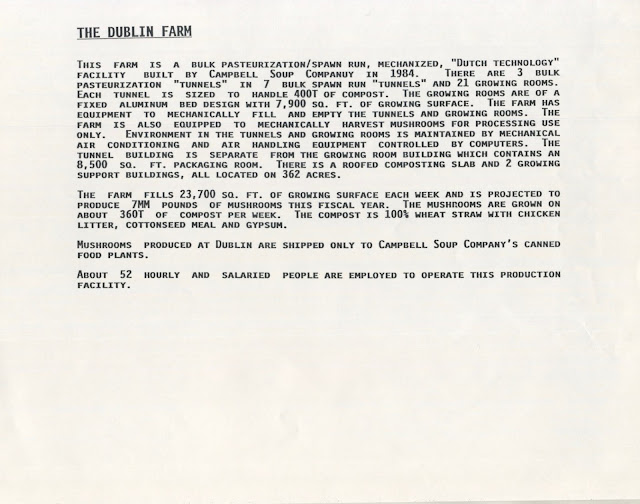

The Dublin farm...

Now the Dublin and Texas plants were again on the market. We had as before, vowed to some serious business people, wanting to purchase the Dublin and separately the Texas plant, to help them start up. But they did not get the full support from the local development authority. There seemed to be little interest in FIGHTING for maintaining this huge employment opportunity.

As a matter of fact, in 1983, when husband Pieter designed the Dublin plant, it was designed for doubling it! BUT the restriction at that time was, that size went above the cheap state loan... and their tax-exempt Industrial Revenue Bonds, so they had to wait for 5 years!

Without enough legal support from the local Chamber of Commerce and development authority, let alone from the Georgia Chamber, these two state of the art high tech mushroom plants got auctioned off in Delaware.

A sleazy business deal, for a fraction of the value and the buyer was ONLY interested in taking out his biggest competitor. There was a clausule built in that no one ever again could grow mushrooms in these plants!

He cannibalized the plants for use at his own mushroom plants across the US...

A very SAD day for both of us! Even more so for our community...

The reason we ended up in Dublin, Georgia and now some 400 jobs out of the window and all the ripple effect of purchasing the wheat straw from all over Georgia, using the waste product (spent lime) of the sugar industry in Savannah, in a great way of recycling. The transport etc. etc.

Both of us also MISS having access to the great spent mushroom compost for the garden...

It was very sad that they went from first quality, closed and firm button mushrooms to open, lower quality soup and canned product. That way also they opened the door for cheap mushrooms from e.g. China. Sure, it saves on the payroll as harvesting is the biggest part of labor but mechanical harvest never can yield high quality...

Campbell Soup decided to sell off all produce plants; a sad day for many that lost their jobs.

Money's a Canadian company loved to purchase the Dublin and the Hillsboro plants but they were kind of forced by Campbell Soup to purchase ALL of their nine mushroom plants!

Both of us had pledged to be involved in starting up again for the new owner and to train the people.

The Dublin farm...

Now the Dublin and Texas plants were again on the market. We had as before, vowed to some serious business people, wanting to purchase the Dublin and separately the Texas plant, to help them start up. But they did not get the full support from the local development authority. There seemed to be little interest in FIGHTING for maintaining this huge employment opportunity.

As a matter of fact, in 1983, when husband Pieter designed the Dublin plant, it was designed for doubling it! BUT the restriction at that time was, that size went above the cheap state loan... and their tax-exempt Industrial Revenue Bonds, so they had to wait for 5 years!

Without enough legal support from the local Chamber of Commerce and development authority, let alone from the Georgia Chamber, these two state of the art high tech mushroom plants got auctioned off in Delaware.

A sleazy business deal, for a fraction of the value and the buyer was ONLY interested in taking out his biggest competitor. There was a clausule built in that no one ever again could grow mushrooms in these plants!

He cannibalized the plants for use at his own mushroom plants across the US...

A very SAD day for both of us! Even more so for our community...

The reason we ended up in Dublin, Georgia and now some 400 jobs out of the window and all the ripple effect of purchasing the wheat straw from all over Georgia, using the waste product (spent lime) of the sugar industry in Savannah, in a great way of recycling. The transport etc. etc.

Both of us also MISS having access to the great spent mushroom compost for the garden...

Related links:

1978 - P.J.C. Vedder's Modern Mushroom Growing Book Published in English | previous post by me

1982 Sinden Award for Pieter at The Hotel Majestic, Harrogate, England | previous post by me

1978 - P.J.C. Vedder's Modern Mushroom Growing Book Published in English | previous post by me

1982 Sinden Award for Pieter at The Hotel Majestic, Harrogate, England | previous post by me

modern mushroom growing 2020 harvesting | our latest book

The Three Most Important Items for Mushroom Production 'Compost, Compost, Compost!' | editorial letter published in CAMPBELL'S NEWSLETTER

Pieter J.C. Vedder's design of Dublin, Georgia/USA Campbell's Mushroom farm at start up stage | video

1985 Campbell Mushroom Plant Designed by Pieter J.C. Vedder | short 1:53 min. video by Pieter

1999 April 7, Vlasic is closing down plant TV35 News—short interview with Pieter J.C. Vedder | short video