In the September issue of Mushroom Business, a redacted article from my husband Pieter got published.

Here first comes the unredacted version... with the omitted part in bold.

IT ARE THE PEOPLE THAT MAKE A MUSHROOM FARM PROFITABLE

Some thoughts from a retired teacher:

Husband Pieter in classroom at his Campbell Training Centre in Dublin, Georgia/USA

Having spent almost my entire life in the mushroom business, mainly in teaching, training and farm reviews, I have learned a number of things. I have learned for instance that growing mushrooms for a profit is for sure a challenging job, that can put quite a bit of pressure on a person. On the other hand, however, it also can give a lot of satisfaction.

Going around the world, as my wife and I did, one can find big variations within the mushroom industry. Many different types of facilities, growing conditions and, not the least; so many different people, each with their own ideas and opinions about what is good. And of course; everybody knowing best. It is quite well possible that one day you can see for instance, a reasonable second break at a farm, on a soaking wet casing layer, and two days later at another farm a second break on a bone-dry one. Both growers try to convince you that this is the way it should be, at least at their farm.

Our Agaricus mushroom must have some characteristics of a strong weed mould, otherwise it would be hard to understand that at certain facilities and under different conditions, it still will produce something. I know that growing 'some' mushrooms, isn't all that difficult; one has to so some real stupid things to avoid some fruitbodies from showing up at all.

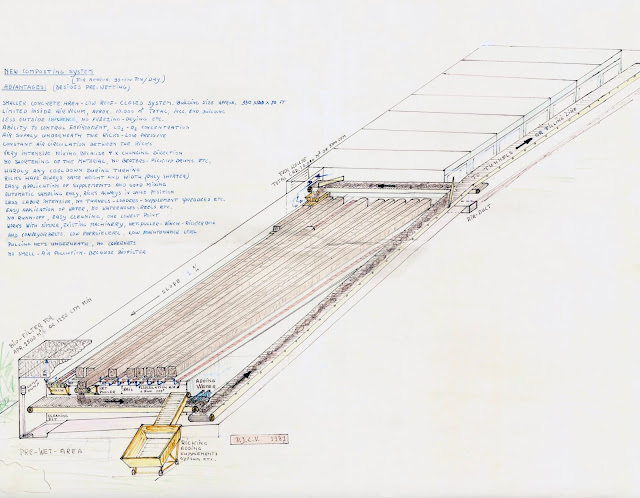

In some books and articles in popular magazines, it's often suggested, that it be relatively easy to grow your own mushrooms in the back yard. This kind of stories might be one of the reasons that for years, and still, some people believe that growing mushrooms is a sure and easy way to make good money. There are also people around, who are interested in convincing a person or company to invest money in the mushroom business, this together with plans and promising calculations, based on high yields, a strong market, and therefore big profit. There are also several companies, especially in Europe, willing (and capable) to build a turn-key, state of the art, but not cheap, mushroom farm, wherever in the world. This complete with all the sophisticated machinery, climate control, and all the modern gadgets, available at present.

What the new farm owner, in whatever country, forgets is, that mushrooms don't grow just on Alcoa racks, but on a nutritious compost; covered with a good casing layer, with the proper moisture level, and in a suitable environment. Therefore, you can expect high yields on a good compost etc. in plastic bags, placed in a somewhat modified chicken barn, in the right climate, and poor yields on a dry, green compost, on the most modern shelf beds. A computer-controlled air conditioning system can do a lot for the production, and quality level, but cannot correct mistakes, made in other areas. It all is in the hands of a bunch of well trained, experienced and dedicated people who make it into a success. If such people are not available on a farm, the owner should spend some money on training the crew, instead of investing in things they are not quite ready for yet. The good pay-off will come from an investment in people; in providing good management, adequate basic training, theoretical knowledge, and also a practical oriented, ongoing training program. Growing mushrooms on a profitable base is by far not that easy, there is a small margin of error, or as my mushroom growing friend Jörg Kuhn once said to me: 'In mushroom growing, wrong is so terribly near to right.'

Modern farms are becoming bigger and bigger, and quite often, the number of problems is growing with the size of the farm. This situation is asking for a strong manager, with experience in this business. The number of employees and the often, high turnover, especially in the harvesting area, is also asking for an ongoing and intensive training program.

Once the new farm has been built, and starts producing, the new owner will figure out a couple of things rather soon. First of all, that the calculations, made before, have been somewhat too optimistic, that it really isn't that easy to get constantly the necessary high yields of good quality on the beds. Secondly, that they didn't realize that it is equally, or even more difficult, to get them off the beds, which will have a big impact on the end results. It all depends on inexperienced, and not properly trained harvesters.

He also will figure out that there is more competition at the market than expected, and that the prices in August aren't as good as last year's Christmas.

The (new) mushroom farm owner thought, that not that much could go wrong, because almost everything was automated, and computer controlled. He now starts realizing that indeed, one still needs a bunch of well trained, and dedicated people, to keep that farm going and making a profit. In most cases, the learning and training process, will start after the farm has been built already; for sure a very exciting, but in most cases, an equally costly period.

Most older farms in for instance Europe or the USA, started relatively small, and grew bigger over the years, so the farm staff could grow with the farm. We see companies in low labour cost countries starting big at once. They perhaps do not realize that, notwithstanding, the eventually built-in technology, success still depends on a number of well-trained and dedicated people.

In my work I have seen examples of some old, but well-maintained farms with wooden shelf beds, no bunkers, hardly any air conditioning and still making good money. On the other hand, very sophisticated, expensive, state of the art farms, highly mechanized, complete with bunkers, computerized etc., that had a hard time for breaking even.

For some years, my wife and I, worked at the huge mushroom farm in Indonesia, where up to 800 tons of compost per day was produced, and then distributed over four locations in the same mountainous area, and therefore, under identical climate conditions. Although using the same compost, strain, casing material etc., the yield and quality varied quite a bit, between the different locations and even within the 30 growing room units, to one another, within the same farm. Certain units always were doing better; yield wise as well as quality. The same ingredients, the same environment, but a different crew.

At the same area, we had a test and training facility with a number of growing rooms. This small farm often got the compost blocks, rejected by the other farms, because of for instance, a weak spawn-run. Nevertheless, the unfavorable start (we gave it an extra week), the yields were often even higher and the quality better than at the 'normal' farms. When discussing this phenomenon with the farm managers, area managers etc., their reply always was the same; that this was simply because of the smaller size of the unit, therefore easier to manage and also having some experienced and more dedicated people. Aha...! So, a well-trained and well-managed group of people can even make up for some other shortcomings.

Therefore, I really don't understand why the mushroom growers as a whole, so far don't spend more time, money and effort, on education and practical training of the farm staff and the workers. Mushroom growing is not manufacturing, instructing the people by simply telling them what to do routinely. You know well, that also ingredients for instance, can be somewhat different and that the growing conditions can change over time. By teaching them some theoretical background and ongoing practical training, the workers will be able to adjust to the new situation. Also, most people show more interest in their job, if they understand what they are doing and why, and how important this job is for the end result. Most people have their pride as well. A good incentive program, not just based on kilograms, but also including quality, which means market value, should be the other stimulating factor, for keeping people's interest.

A good farm manager should utilize every opportunity to organize learning activities for himself and his crew, increasing their knowledge and skills, and at the same time, creating a strong team spirit.

In our work, we often experienced a gap between the managing staff and the farm workers. We had the feeling that certain farm managers, staff members, and even area managers, weren't supporting the idea for ongoing training programs for the workers. They say, it costs too much time and they themselves know already everything...! Besides that, they are afraid to lose some of their authority (whatever that may be). What a pity, they could gain so much respect, and even learn from their workers, because they know exactly the daily problems. Sometimes, the workers are even smarter than you think they are.

Pieter showing his students how to check compost quality by making hands dirty

We know some farm managers, and even area managers, who don't like making their hands and shirt dirty and thus run the farm from behind their desk, in front of a computer screen, afraid of walking in the run-off at the compost slab or in the 'dripping' growing rooms. The manager and area managers should have dirt under their fingernails, otherwise they will never know what really is going on at the farm, but they nevertheless are making decisions, related to growing. This often creates some tensions amongst workers and the staff.

In a consulting job, going over the farm with the manager, I often had the feeling that this was the first time in that week, that he had been at the slab or in the rooms. I know rather well that being the farm manager is a demanding job (hopefully he gets paid for it). Even in the weekends, those watering boys need some guidance. Daily routine is not a good thing on a mushroom farm, because we are dealing with a growing process, where constantly there are chances that certain elements could have changed, so we have to react to that. Here gain: 'In mushroom growing, wrong is so terribly near to right.

Mariette training harvest supervisors in Indonesia

Foot note: Both of us have always done our consulting work, based on QUALITY which is market value, instead of just high yields...! A BIG mistake would be an incentive program for the managers (even consultants) based just on kilograms but not on quality, which translates into market value!

We know some farms where the harvesting manager never has picked mushrooms, him or herself. How in the world can such a person give the necessary training and proper instruction with guidance about how, and what to pick, grade and clean the beds, etc.? No wonder that on such a farm the people don't have much respect for their 'boss'. An area manager or harvester supervisor doesn't need a degree, but first of all should have experience, knowing all the tricks involved in harvesting, and by doing it him/herself for quite some time, meanwhile participating in all kind of training activities. He, or she should also have the ability to handle people well and also be able to train and instruct the crew, some of them even speaking a different language. We know that quite often they give that new harvester a knife and send him/her with the crew in for instance room six, where he/she will pick up the good, as well as the bad habits. Mushroom farms nowadays are becoming bigger and bigger, and the responsibility of the manager is growing with it. A size related problem will also be to find constantly enough harvesters in the surrounding area; therefore, they often have to rely on 'imported' people. We know that the turnover in the harvesting crew normally is rather high and therefore an ongoing training program is even more important.

Again, it is the well-trained, well-paid and dedicated people who make a mushroom farm successful. The farm will gain more from money and time spend on practical oriented training activities at the farm, then spending it on those, high cost international happenings, congresses and whatever meetings. To me, it looks like the organizers of some of those activities, have a preference for far away, exotic places, and for high cost accommodations. (I have been at several of those). This automatically creates a situation that only a limited group of privileged people can attend, like owners of a big farm, representatives of supply companies, general managers etc. They are perhaps a good auditorium for listening to the latest research results, marketing strategies etc. The right people however, listening and discussing lectures about more practical topics, like composting, phase II, watering, flushing, supplementing and all kind of growing related matters; the people with 'dirt under their fingernails' stay back at the farm. Research of course is important for the industry, but the equally important thing is 'to translate' the available knowledge into growers' language and present it to the right group of people at the farm.

We have to realize that there are still a number of farms that cannot afford to send somebody abroad for a course or for having 'an expensive' consultant. For several years we have done consulting and training work for farms all over the globe. Often, I was wondering why they have to pay me, to get on my knees, for showing them the rubbish underneath the beds, or why they cool down so early and too harsh, or that there are still dry straw lumps after pre-wet, that the casing after the first break is too dry and that clustering is not related to a spawn quality but more than likely, the result of a sloppy job at distributing the supplements or cac'ing material. That they better follow the CO₂ concentration with an instrument and not whether you still can breathe inside the room or become unconscious. At least, we always tried, after going intensively over the farm, to find enough time with the staff and the workers to go over the shortcomings. We also built in some theoretical knowledge, so that everybody has a better understanding about why certain things can go wrong.

For sure, a well-educated, trained and experienced consultant can be a help in certain situations, but the fastest and most economical solution would be if the people at the farm would have enough background knowledge to recognize and solve the problem themselves. Most of the aforementioned problems, the symptoms and the solution for sure can be found in a good book. Such a book could be the base for an ongoing training program; not just telling the workers what you expect them to do, but also teaching them some background so that they better understand what the parameters are, so that they can make the right decision themselves in somewhat different situations. Especially in the harvesting area, an ongoing training program has to be carried out and that for several reasons. First of all, the quality of the product is for a big part in the hands of the harvesters. They also can do quite a bit of damage to the next break(s). Show them the pictures; if they know the symptoms, they are the first who discover some abnormalities, mouldy spots, mites, dry spots, virus etc., and inform the grower. Besides that, they also are a big chunk of the labour pie, and very often one has to train newcomers.

Again, a good book should cover the basics, theoretical background and practical knowledge and experience. As the writers of such a book, we realize quite well that, once in a while, there will be a new development, but the overall basics will forever be the same. A magazine like Mushroom Business, can keep you up to date about new developments, like new equipment, new strains, marketing info, etc. Most of the available literature is written in English language, like our newest; modern mushroom growing 2020 harvesting, written by me and my wife, who has also an almost lifelong career in that area. We expect, that on most farms, there will be at least one person who can handle that language.

Am I promoting this book? Of course, I do, but for some different reasons as you perhaps think. We have spent quite some time, and a good bit of money, no sponsors, to produce a quality book, inside and out, but we don't need to make money on it. We would be happy if we are breaking even. The main reason for us to do this, is that we like to give the mushroom growers a guide and tool to do what we so strongly believe in and what we have done almost our entire life. We are convinced that one of the most important tasks of the people who are responsible for the success of the farm and everybody involved, is creating a loyal and well-trained crew. We hope that this book will be a worthwhile gift to an industry we both still love so much.

Pieter J. C. Vedder

MUSHROOM BUSINESS September 2020

People Power

Pieter Vedder on people power

People make the difference

No use for retyping the above printed and somewhat shortened version.

Of course we do understand that space in such a magazine is limited due to the advertising...

Related links from previous posts by me: